Nickel

Nickel 405

Specs: QQ-N-281, ASTM-B164, AMS 4674, ASME SB164

UNS#: NO4405

Nickel 405, a versatile alloy, has become a go-to material for engineers and machinists tackling the complexities of industrial manufacturing. Known for its resilience, this alloy offers properties that make it indispensable for various industries, from chemical processing to marine environments. If you need to replenish your stock, Wieland Diversified offers reliable products at a price that you’ll be happy with. We take the guesswork out of your metal alloy purchases.

Common Applications of Nickel 405

Below are some of its most common applications and the industries that rely on it.

Chemical Processing

Nickel 405 excels in environments exposed to corrosive chemicals like hydrochloric and sulfuric acids. It’s commonly used in chemical processing equipment such as heat exchangers, reaction vessels, and piping systems.

Marine Applications

Because of its superior corrosion resistance, Nickel 405 is ideal for marine environments. It’s frequently used to manufacture propeller shafts, marine fasteners, and pump components.

Oil and Gas

From wellhead components to drilling equipment, Nickel 405 is trusted for its durability under the extreme conditions of oil and gas operations, including exposure to saltwater and high pressures.

Electrical and Electronic Components

This alloy is also utilized in electrical applications for its thermal stability and high conductivity. Switchgear, connectors, and other precision components often leverage Nickel 405 properties.

The higher sulfur content of Nickel 405 allows for enhanced machinability, making this alloy the free machining grade of Nickel 400. Similar to Nickel 400, 405 is a high-Nickel alloy consisting of at least 63% Nickel alloyed with Copper, some Iron, and other trace elements. This material is valued by many industries for its combination of high strength and corrosion resistance over a wide range of conditions and temperatures.

Nickel 405 exhibits many of the same corrosion resistance and physical properties as Nickel 400, however, the range of mechanical properties does not completely mirror those of Nickel 400. This grade is used primarily as automatic screw machine stock where corrosion resistance and toughness are required.

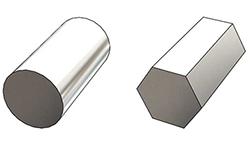

Available shapes – round and hex

Not all materials are equally effective, and Nickel 405 leads the pack when it comes to balancing performance and machinability. Its unique properties solve multiple challenges faced by industrial manufacturing teams, making it an indispensable asset in projects demanding strength, precision, and speed.

Engineers benefit from a material that stands strong in corrosive environments, while machinists appreciate the ease of processing it compared to other nickel-based alloys. It’s this dual advantage that cements Nickel 405’s reputation as a go-to alloy across industries.

If you’re ready to reap the benefits of Nickel alloy 405 in your industrial processes, Wieland Diversified has experts on hand to answer any questions you might have. See how you can get more out of your metal alloy investment!

Tools

Related Products

Get a quote for Nickel 405

About Us

As part of the Wieland Group since 2018, Wieland Diversified will be able to continue to provide its customers with the quality and service they have come to expect. Learn more at Wieland.com

Contact Us

Wieland Diversified

49 Main Street

PO Box 65

Monson, MA 01057

p (800) 628-3035

p (413) 267-5101

f (413) 267-3151

Follow Us

Copyright 2021 © Wieland

All Rights Reserved. Privacy Policy